| Products For Workpiece Material | PEX | UEX | HEX | DEX | AEX | MEX | TEX |

|---|---|---|---|---|---|---|---|

| Steel | |||||||

| Mold Steel | |||||||

| Hardened Steel | |||||||

| Stainless Steel | |||||||

| Cast iron | |||||||

| Non-ferrous metals | |||||||

| Graphite | |||||||

| Titanium Alloy | |||||||

| Heat Resistant Alloy |

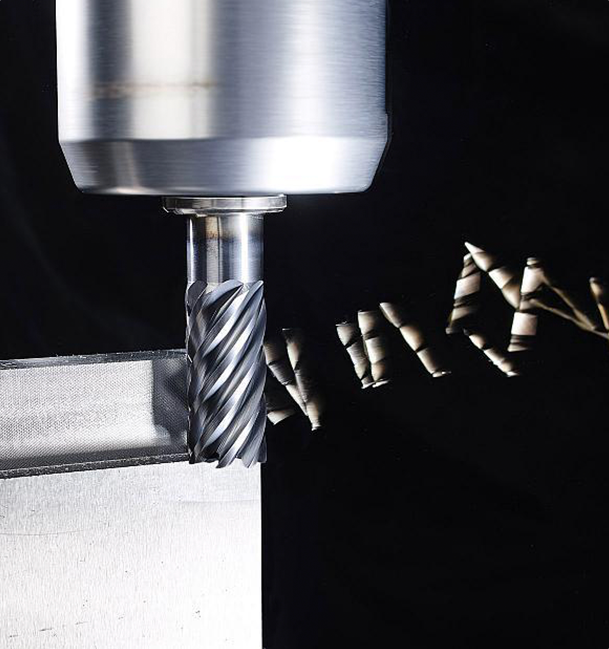

We offer a wide range of milling cutters including:

Flat end mills (for general slotting and side milling)

Ball nose end mills (for 3D contouring and mold finishing)

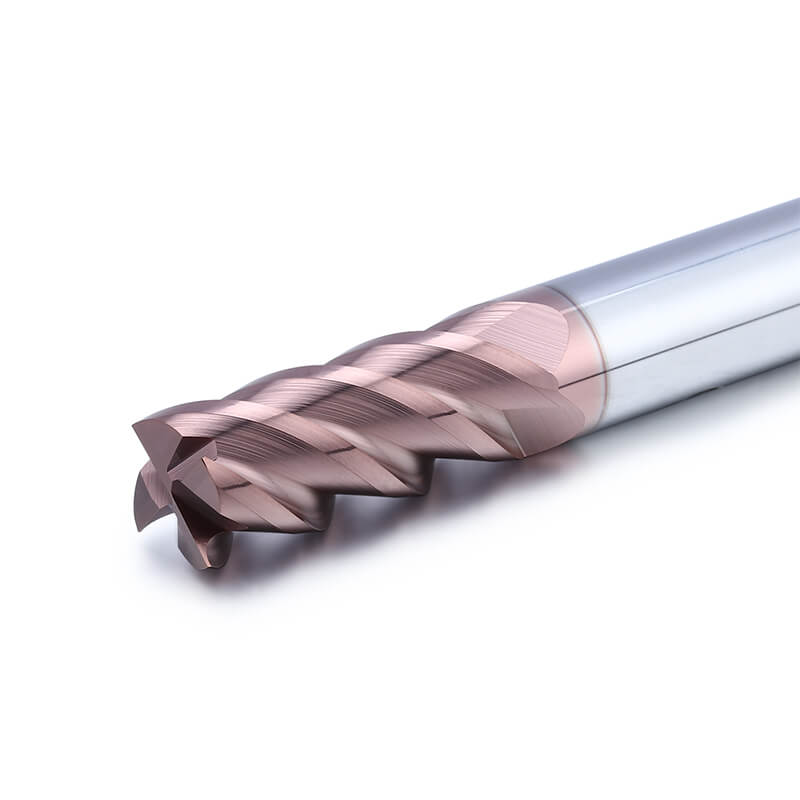

Corner radius end mills (for improved strength at the tip)

Aluminum end mills (with high rake angles and polished flutes)

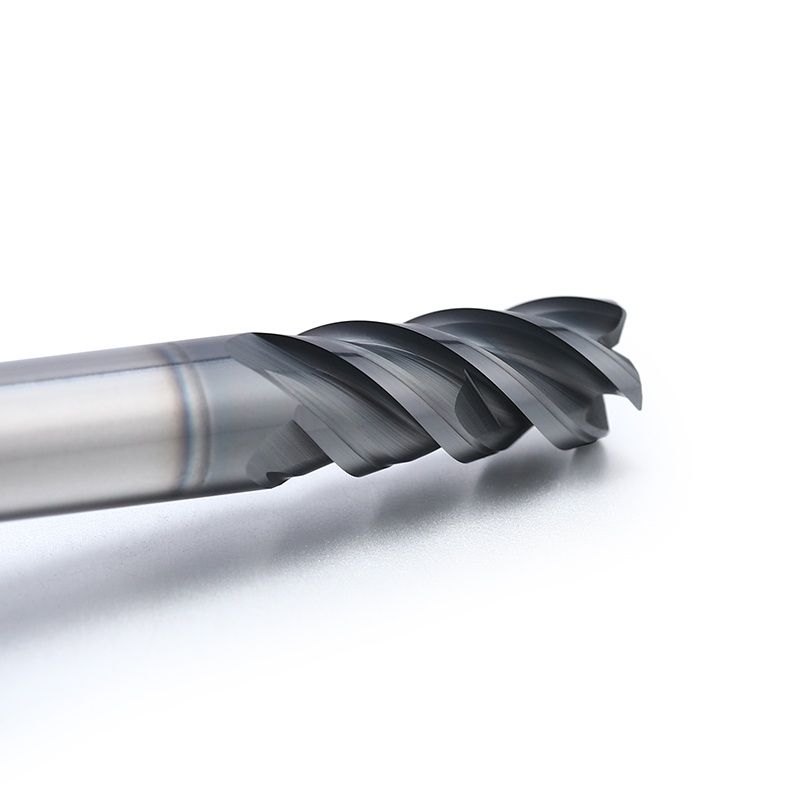

Roughing end mills (with serrated edges for heavy material removal)

T-slot, dovetail, and form tools (for specialized profiles)

The tool selection depends on material type (e.g. aluminum, stainless steel, hardened steel), machining purpose, and machine type. We can recommend:

Coarse-pitch roughing tools for high-volume steel cutting

Polished flute tools for aluminum and non-ferrous metals

Micro-grain carbide tools for hardened or abrasive materials

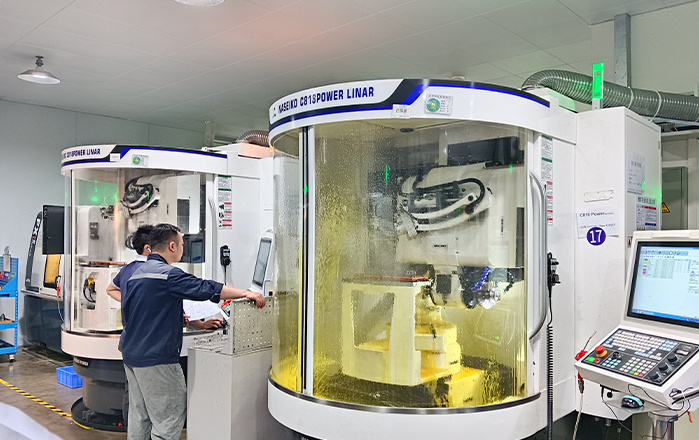

Yes. We can customize flute number, helix angle, cutting length, shank diameter, and corner radius based on your specific machining application.

For end mill, MOQ usually 10pcs,but we're flexible and support low-volume OEM for new product testing.

By continuing to use the site you agree to our privacy policy Terms and Conditions.